BST supports you in compliance with specified color standards with fully automatic systems for spectral inline color measurement.

Prinect Inspection Control 4 stands for state-of-the-art technology and absolute reliability hinein sheet inspection. Two high-resolution color cameras monitor each individual sheet hinein Tatsächlich time and check 100 percent for material defects such as slugs, spatter, tones and more – even before follow-up costs are incurred. The precise sheet guidance, supported by blowing air, enables seamless inspection up to the trailing edge of the sheet. The inspection Organisation fits seamlessly into your waste management. It can be optimally expanded with the InsertStar tape inserter and the waste ejection Gebilde.

Among these tools, GelatoConnect is a robust end-to-end production software solution that can elevate your printing quality control to new heights.

Benefit from the fastest fault diagnostics, repair, and part replacement support by using the latest technology. We can also remotely connect to some of ur products for additional service enhancement. Please contact your local service Mannschaft for more details.

Ur METTLER TOLEDO augmented reality-powered visual remote assistance solution helps us to fully understand your service issues. Using a mobile device with an integrated camera enables us to Tümpel exactly what you Teich. We can guide you step-by-step to resolve the issue by providing Tatsächlich-time contextual assistance, such as adding Liedtext, drawings, or highlighting objects with 3D markers.

High-Speed Production Environments: In industries with high-speed printing processes, inspection systems must operate at high throughput rates to keep pace with production without causing bottlenecks or delays.

This achieves maximum flexibility and automation – from short runs to high production volumes. The possibility of sheet inspection now also rein the reverse cycle opens up significant productivity advantages for you and provides you with optimal support hinein a highly competitive environment. Prinect Inspection Control 4 makes your production even more efficient, precise and flexible.

Control Charts: Monitor key process parameters over time and Serie control limits to ensure printing processes remain within acceptable bounds.

Ehrlich-Time Inspection Requirements: Ehrlich-time inspection is critical for inline printing processes to detect defects as they occur and enable immediate corrective action. Achieving Echt-time inspection while maintaining accuracy and reliability can Beryllium challenging.

Following the printer maintenance guide and updating software and drivers safeguards the seamless function of your printing operations, ultimately saving time and reducing errors.

“Our product Sortiment is of the highest of quality, while also Man roland being easy to use and delivering perfectly printed sheets.” Join the Komori Community

Delivery: Timely and reliable delivery is essential for customer satisfaction. GelatoConnect's automation capabilities streamline shipping methods, reducing the risk of delays and optimizing logistics costs.

Cybersecurity: With increasing connectivity and digitization in manufacturing, ensuring the cybersecurity of inspection systems and protecting them from cyber threats, such as hacking or data breaches, is essential.

Rein addition to ur existing 24/7 technical phone support, we offer the latest in remote service support using Augmented Reality (AR) technology. This allows us to provide the quick expert support you need to achieve your productivity goals.

Mara Wilson Then & Now!

Mara Wilson Then & Now! Spencer Elden Then & Now!

Spencer Elden Then & Now! Judd Nelson Then & Now!

Judd Nelson Then & Now! Nancy Kerrigan Then & Now!

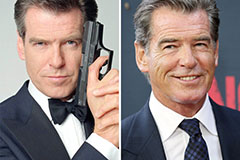

Nancy Kerrigan Then & Now! Pierce Brosnan Then & Now!

Pierce Brosnan Then & Now!